Welcome to Northern Brickworks.

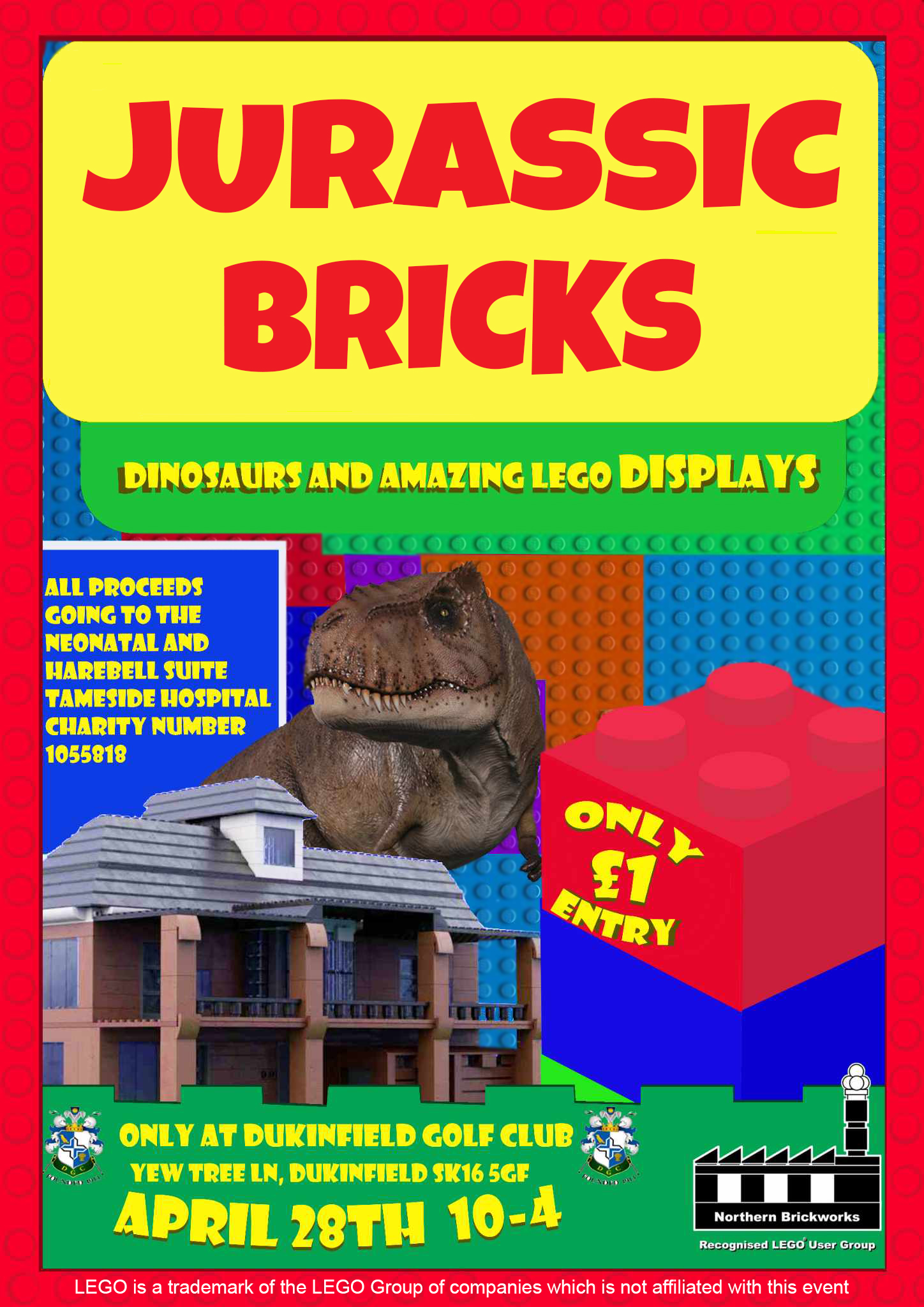

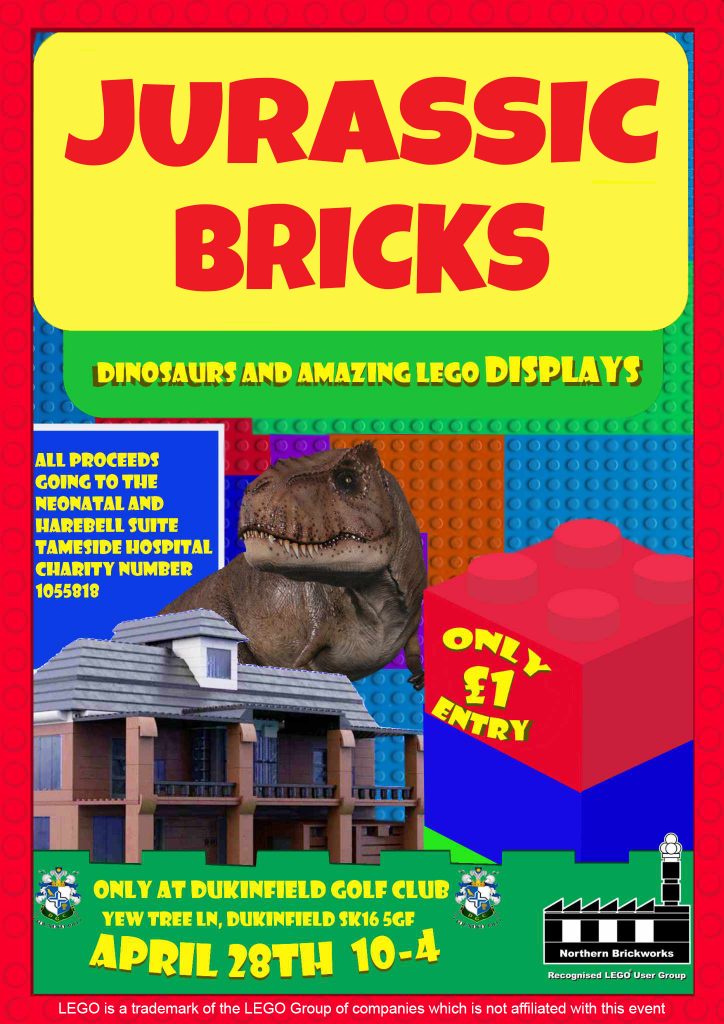

JURASSIC BRICKS 2024

Our next event after North Notts is a brand new show for 2024 hosted by member Cameron.

Jurassic Bricks is being held at Dukinfield Gold Club , Tameside, Greater Manchester on Sunday 28 April 2024. They’ll be a wide range of LEGO displays at the event plus life size dinosaurs courtesy of ICatching Events!

This is an event for all the family and entry is only £1

North Notts 2024

It’s a new year and that means shows are back! The North Notts Brick Show returns to Worksop in March, and we’ll have regular shows throughout the year. Keep checking back for more details, or go to the events page where you can add events directly to your calendar.

Our final show for 2023 was Ste Scriven’s Monkey Bricks. You can find a report and pictures from the day right here

Trafford Centre Store Opening

Northern Brickworks members attended the opening of the new LEGO store in Manchester.

Our intrepid reporter Robert, provides an overview of The LEGO Groups new store in Manchester’s Trafford Centre!

Click HERE to read the full report

A brand new page has joined our website, featuring reviews of off the shelf LEGO sets, be they classic or recent. If you would like to provide a review of your own, drop us a line at the contact us email address, along with a few paragraphs and some pictures and we’ll try and feature them from time to time.

In the mean time we have a view of the Creator LandRover set here from one of our members.

Our second review can be found here

Spindles Town Sq Show – Success!

Northern Brickworks members descended on Oldham’s Spindles Town Square Shopping centre in September for a new show. Making their debut as show organisers, husband and wife team Mark & Judi Kraska did a superb job of attracting both established exhibitors and a few new faces.

Split over two empty store units, this free event was designed to bring people back into the centre, and it did that in spades! Over 3500 people crossed the unit doors with the shopping centre seeing a 14% increase in footfall for the day. Several other businesses in the centre also joined in.

Plus there was face painting and several local charities were in attendance. Feedback was extremely good and you can see some of the pictures from the day here.

Past Events

Two amazing brick shows took place in July, firstly Sale, Manchester returning for a second year. The warm failed deter the crowds and over a £1000 was raised for the Church.

Pictures from the Sale show can be found here.

A week later Rhyl Building Bricks returned raising funds for the local foodbank and Fairy Bricks.

You can find pictures from the Rhyl event here.

Lymm Transport Day

The show was back with a bang and over 2000 people made their way through the displays. y!

Social Evening Meets

If you would like to see what our members get up to or have been thinking about joining, why not pop along to one of our social evening meet up which happen in various locations. Check out the EVENTS Calendar for further details. You’ll find lots of like minded adults at these events, there are normally activities, a chance to show off your latest builds, or just sit and talk about everyone’s favourite brick.

New Events Calendar

We’ve been working behind the scenes to update the list of events and exhibitions taking place. Gone has the boring old Exhibition List and in comes the Events Calendar! This list all sorts of events from Exhibitions to Virtual and In Person Meetups. Click the link on the top bar or here to find it. You can even subscribe to it so you never miss a thing!

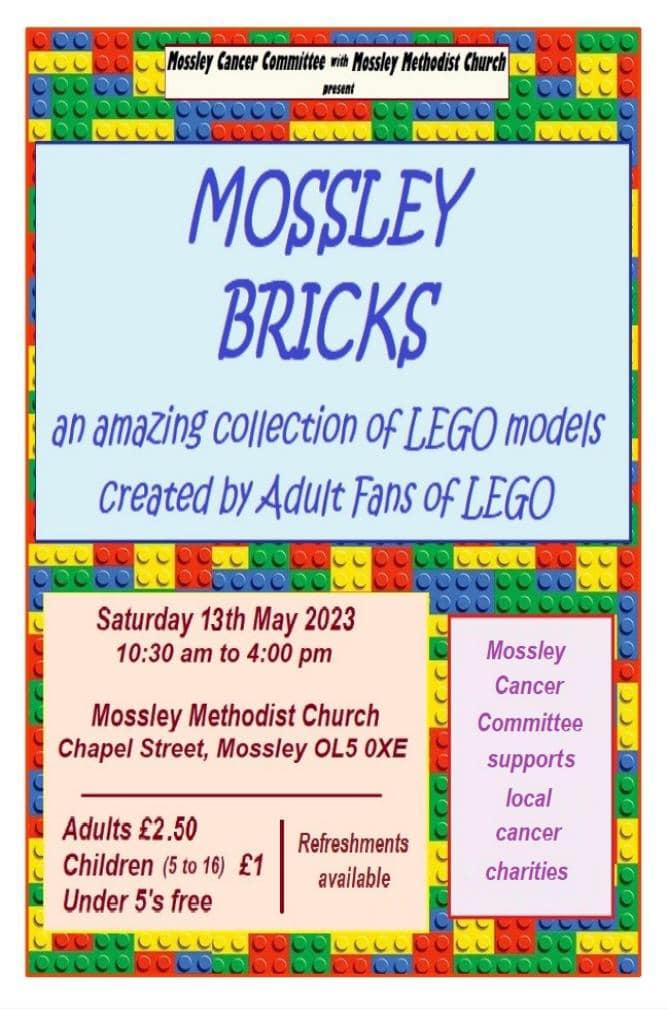

Mossley Brick Show 2023

The small show with a huge heart was another tremendous success raising nearly a thousand pounds for local causes. A huge well done to Val and Robert for organising this amazing community event.

Mossley seems set to return inn 2024! More details very soon.

North Nott’s Brick Show 2023

Northern Brickwork’s Premier Show returned to Worksop for the first time since 2019.

Over 800 came through the doors raising money for our favourite charity Fairy Bricks.

You can see pictures from the event here.

Bricktastic – Fantastic!

What can only be described as the UK’s best Lego Fan event took place in Manchester over the weekend of February 25 and 26th. Over 9000 visitors came to support Fairy Bricks as they presented builders from all over the world. For this years event, there was a small change in venue as it moved into the former train station that is Manchester Central having previously been in one of the smaller halls.

Covering just over half of this magnificent venue there were truly sights to be seen and bargains to be had!

Northern Brickworks members provided a number of exhibits and our own Steve Guinness retained his Lego Master pedigree when along with Gary Davis they won the inaugural Bricktastic Masters competition!

You can find more images from the event in the picture gallery.

Bricktastic will return in 2024

Our new, and hopefully monthly, feature is now live and can be found on the articles page or by clicking here

FREE FAMILY FUN WITH THE NEW LEGO FRIENDS

Discover the new LEGO Friends characters with free, exciting activities in

LEGO Stores and beyond this February and March

- Throughout February and March, visitors to select LEGO® Stores will be able to discover the new LEGO Friends characters through free and exciting building and in-store experiences

- From the 18th-21st February in the Bullring, Birmingham, a giant LEGO versions of the Friends bedrooms will be on display, where kids can meet and take part in awesome activities with their favourite influencers

Throughout February and March, families can discover the new LEGO® Friends through a series of free events. The 2023 LEGO Friends Universe includes characters with a wider variety of skin tones, cultural backgrounds, disabilities, and neurodiversity, all with authentic personalities and relationships.

To celebrate the new LEGO Friends characters, the LEGO Group have a fun packed schedule of FREE events happening in select LEGO Stores and beyond. These include:

A two-month long play experience taking place in LEGO Stores from 6th February – 2nd April, with free activities including:

- Discover the LEGO Friends: spin the wheel and find out more about one of the eight new LEGO Friends characters – and then build a set that aligns with that character’s passions before proudly displaying it in-store.

- LEGO Friends Skate Ramp: During half term on Wednesday 15th and Thursday 16th February between 2-4pm come in-store to create a LEGO Friends Skate Ramp – that you can take home to play with your friends on

- LEGO Friends Character Creator: in March you can design and customise your own LEGO Friends character (check with local store for exact timings).

- The LEGO Friends Bedrooms: Four of the new Friends LEGO bedroom sets will be on display for visitors to play with and customise.

- Giant brick LEGO Friends: In the London Leicester Square Store you can grab a photo on the LEGO bench surrounded by giant brick versions of Nova, Aliya, Autumn and Leo. Plus scan the QR code to reveal the remaining four friends.

- LEGO® Friends ‘Hangouts’ – 18th – 21st February, The Bullring, Birmingham, UK. A child’s bedroom is an integral part of forming their self-identity. At this event, kids can meet and take part in awesome activities with their favourite influencers as they explore creativity and self-expression, form friendships and learn what it means to be different together.

The LEGO Group recognises the importance friendships have on child development and how it plays a huge part in helping kids understand diversity. Further to the launch of the new generation of characters, the storylines within the LEGO® Friends Universe have been refreshed in collaboration with the Geena Davis Institute on Gender in Media, helping to develop narratives that ensure they’re relatable, inclusive, and reflective of the real-life experiences of children today. Content drops from 29th February 2023.

There are loads of ways LEGO fans across the UK can engage with the new LEGO Friends including free in-store building experiences at LEGO Stores, four giant versions of the LEGO Friends bedrooms being brought to life in Birmingham and a LEGO Friends Dream Bedroom competition.

For more information about LEGO Friends activities happening near you visit www.lego.com/stores and search for your local store. For more information on the new LEGO Friends on the www.lego.com/friends. To enter the LEGO Friends Competition, visit www.promoentries.com/LEGOFriendsDreamBedroom.

Floss’s Fantastic Flowers

Spring is just around the corner but if you cannot wait or just want something to brighten a winters day, take a look at these amazing botanical creations from Floss. Seen here at a personal event they truly are magnificent, to take a closer look click HERE to find a whole plethora of colourful blooms!

The festive season is upon us.

The end of the year approaches and that means its nearly Christmas! What will you find under your tree or at the end of the bed. Will you finally grasp that holy grail set or is it something from the current range that you’re longing to have.

It’s also time to look forward to 2023 and plan what we’ll be doing in the forthcoming year. Events are already being announced with many more to be come. Here at Northern Brickworks we will hopefully be revealing a brand-new show for February, more details soon. Plus, our flagship North Notts show returns after a few years in the pandemic wilderness.

So, get building and we may see you at one of these great events! And if you’re not sure where to start don’t forget to check out the guide to exhibiting on the articles page.

Merry Christmas and a Happy New Year from Everyone at Northern Brickworks.

Exhibiting – Where to start

Perhaps you fancy having a go at being an exhibitor but are not really sure where to start. I’ve written an article about this which can be found HERE. Have a read and if this is you, why not look to apply to one of the shows already announced. Don’t worry if they’re not near you, more will be announced soon.

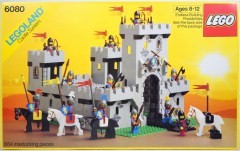

The Lion Knights – A Fan History

You can now find the entire Lion Knight History as told by our member Robert Martin in the articles section! If that isn’t enough, you can find the history of the Black Falcons in the same section.

They’ll be more from Robert in the new year as well.

Get Involved with Northern Brickworks

There are many ways to get involved with Northern Brickworks activities. When there are no events taking place, you’ll still find our members are keeping busy, whether it be building new models for their next event or offering help and advice to others, this is a friendly community after all!

A number of our members hold monthly meets from online social meets, via the Zoom platform plus there are physical meets in Sheffield, Manchester and North Wales. You can find details of all these on our forum, there’s also private Facebook group if you prefer the social platforms.

If there isn’t anything taking place where you live why not start your own? We can offer help and assistance if you need it.

Northern Brickworks Premier Show returns to the calendar for 2023, so mark the date in your diary now – Saturday 25th March 2023 at Outwood Academy Valley, Worksop. Details on how to sign up to exhibit can be found here